This post deals with replacing the cable on the Minelab Excalibur’s unit. To read about how to replace cable on the coil end go here

Minelab Excalibur’s good old cracking cable

Removing old cable from unit

a. Cut off cable just outside unit if you dare. Otherwise leave it and try to get the unit opened up first. If it doesn’t work out, be happy you didn’t cut it. Continue using Excalibur with broken outer shell.

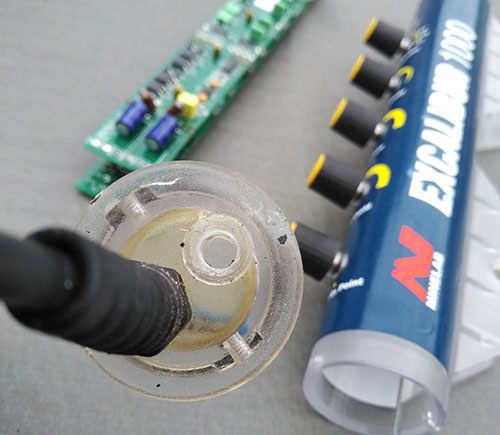

b. Opening up the endcaps: Take off the black plastic cover around endcap. You will need it again. Screw off of the black thing that sites over the cable entering the unit with a small wrench. And Don’t forget to put BOTH over your new cable BEFORE SOLDERING. Screw the 2 screws in the endcap out (they are under the black cover), then fiddle with some thin flat screwdriver or a razor (seems dangerous) to get the end cap to move. It’s all in this video.

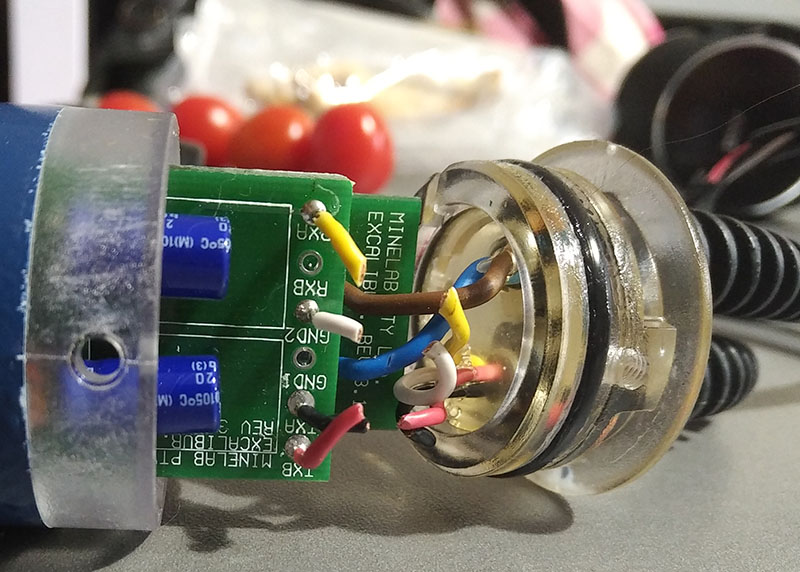

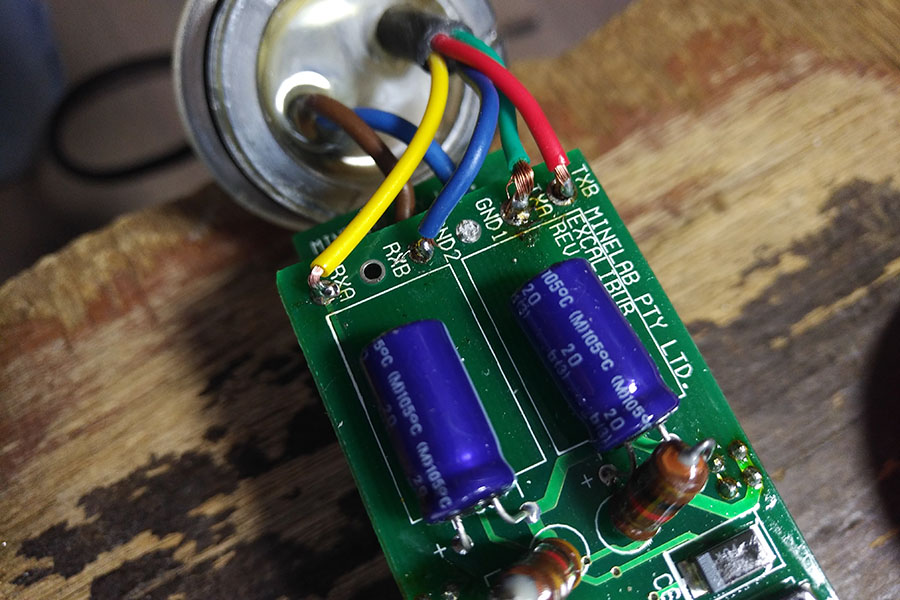

c. In order to slide out the motherboard, you will need to open the end cap on the other side to release the 2-pin audio cable. It’s only a connector, so no need to solder. There might be a third ground wire that needs to be cut, but this is not with all Excaliburs. This is how it looks without the unit’s cover.

d. Turn all knobs to the utter left position. Pinpoint and treshold are pointing downwards, the rest points to the 0 or extreme left. This creates a free passage for the board’s components to pass through. You can look inside while trying to get it out and see how it is sitting.

Pity i don’t have pictures but there are other sources if you google it.

Don’t forget to figure out how the wires are going to go. Look at what you have, or make a picture to be sure. Just make sure, whatever wire coming from the coil is attached to its original end hole in the unit board.

The old wires have to be removed from the board. First cut them off near the endcap, then remove the solder and pull them out.

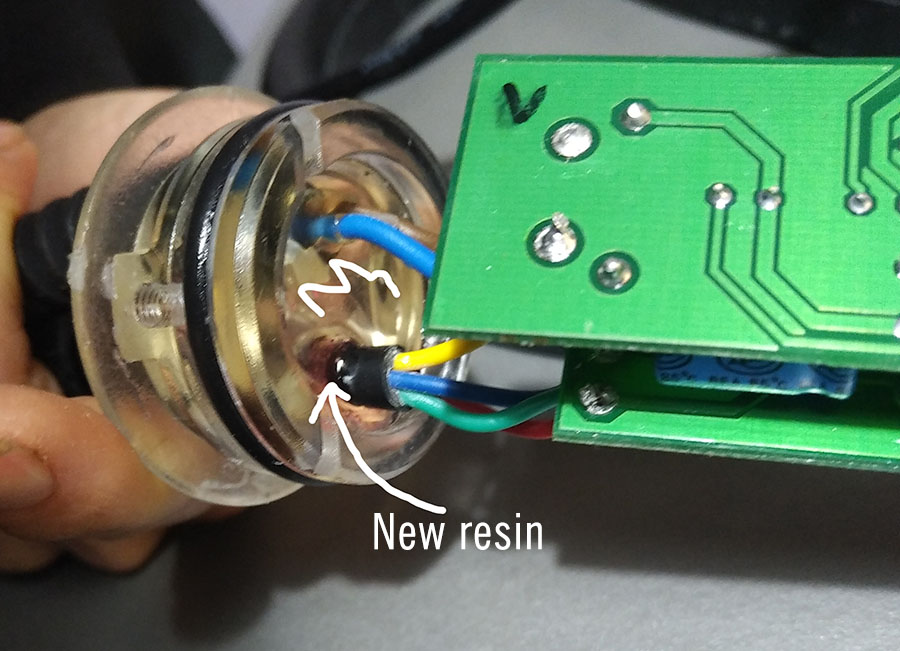

The cable goes through the end cap resin, so you need to drill that out. I cut off the cable as far as I could, then started drilling through the cable from the outer side with a smaller drill bit first. Takes a while to get a grip but it worked in the end. Just see that the hole you drill is big enough for your new cable. It doesn’t have to be bigger.

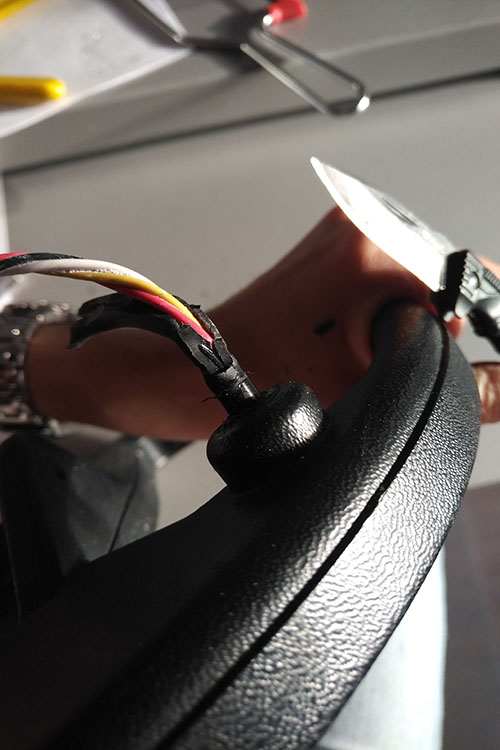

Now you have to stick the old black endcap cover and cable end over your new cable before plugging it into the endcap:

Put cable through endcap hole and solder the right wires to the board:

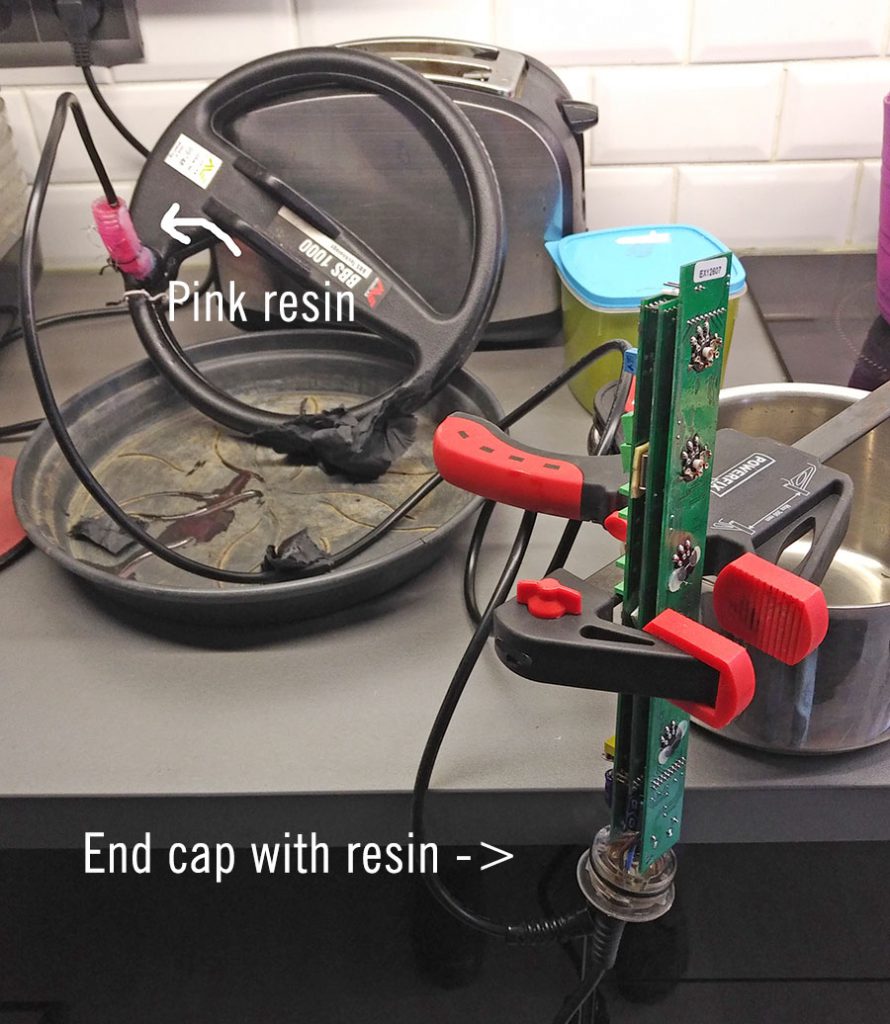

Add resin to the endcap to waterproof it.

Time to put the board back into the unit. Good luck with that 😀 Remember, if the endcap doesn’t seem to close, the 2 holes in the inside are supposed to go over the green board so twist it a bit and see if it gets to that.